1. The characteristics of TPE resistance band

TPE material has good resilience and tensile strength, and it feels comfortable and smooth. It is directly extruded and formed by an extruder, and the processing is simple and convenient. TPE has relatively poor oil resistance. TPE burns with a faint aroma, and the smoke is relatively small and light.

TPE material is a blended modified material, and its physical properties have a lot of adjustability, and the specific gravity is between 0.89 and 1.3. The hardness is usually between 28A-35A Shore. Too high or too low hardness will affect the performance of the resistance band.

The TPE resistance band material uses SEBS as the main material. SEBS is also an environmentally friendly material that meets the REACH standard, so it will not cause allergic reactions to special groups. The elastic belt made of TPE has a smooth surface, no particles and foreign matter, and still maintains excellent elasticity in a low temperature environment without being hard and brittle. Excellent weather resistance, it can be used in an environment of 40-90 degrees Celsius, and there will be no cracking in outdoor use within this temperature range.

The main material used in TPE, SEBS, contains a large amount of butadiene, which has the characteristics of high stretching ratio and small deformation. We tested that stretching 3 times for more than 30,000 times will cause a little deformation, but not more than 5%.

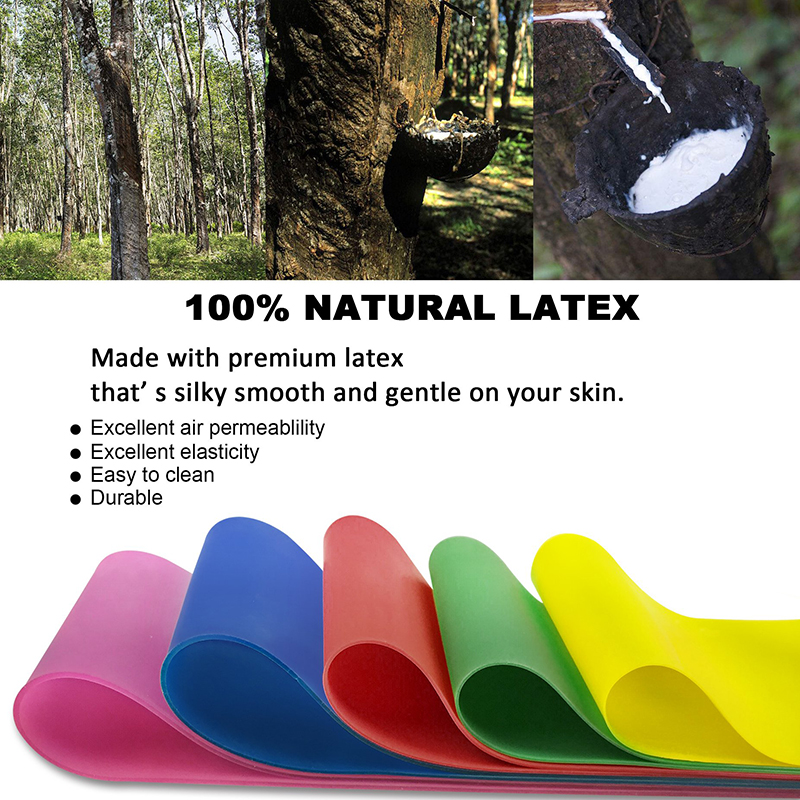

2. The characteristics of latex resistance band

Latex has good wear resistance, heat resistance, super high elasticity, tear strength and elongation more than 7 times. It is easy to age in the air, whitening when spraying frost. Due to the presence of heterogeneous protein molecules in natural latex, it may cause allergic reactions in certain people.

Natural latex is cut from the rubber tree. It is a kind of natural rubber. It is liquid, milky white, and tasteless. Fresh natural latex contains 27% to 41.3% of rubber content, 44% to 70% of water, 0.2% to 4.5% of protein, 2% to 5% of natural resin, 0.36% to 4.2% of sugar, and 0.4% of ash. In order to prevent natural latex from coagulating due to its own microorganisms and enzymes, ammonia and other chemical stabilizers are often added.

Resistance band latex is better or tpe is better, both have advantages and disadvantages. Used in the field of resistance bands, the choice of TPE material is fully capable of its use function, and the price is cheap. Comparing the two materials, there is no good or bad. We still have to decide according to the performance and application requirements of the product.

2. The difference between TPU resistance band and TPE resistance band

Although TPU and TPE are a letter difference, the use of TPU resistance band and TPE resistance band is far different. The petite figure of the TPU resistance band shines in the field of knitted garment accessories, such as the collar and cuffs of knitted garments, the shoulder seam and the side seams. What TPE elasticity takes is that the strength route has a certain status in fitness equipment, such as fitness resistance bands, fitness equipment tension bands and so on. Whether it is TPU resistance band or TPE resistance band, they are environmentally friendly and durable. The most fundamental difference between them is the difference in appearance width and thickness and the scope of use. Of course, the raw materials are also slightly different.

1. The difference in appearance and scope of use

The color of the TPU resistance band is mainly transparent frosted, generally the width is between 2MM and 30MM, and the thickness is between 0.08MM and 1MM. It is applied to the collar and cuffs of knitted garments, and the shoulder seam side seams are shaped to give a good invisible effect. There is no need to consider the color matching; its width is usually similar to the width of the stitches, which makes it easy to hide the belt; the relatively thin thickness will not affect the comfort of knitted garments after sewing.

The color of TPE resistance band is more diversified, such as natural color, blue, yellow, green, red, orange, pink, purple, etc. The general width is 75-150mm, and the thickness is 0.35mm, 0.45mm, 0.55mm, 0.65mm, etc., The colors are diverse and convenient for users to choose. Because the TPE resistance band is wider and thicker, it can withstand better tension and is suitable for use on fitness equipment.

2. The difference between raw materials

Both TPU and TPE are thermoplastic materials with rubber elasticity, and both have good rubber elasticity. In comparison, TPE is more excellent in terms of tactile comfort, and TPU has more excellent elasticity and strength. It is difficult to distinguish between TPE and TPU by visual observation alone. Start with the details to analyze the differences and differences between TPE and TPU:

1) The transparency of TPU is better than TPE, and it is not as easy to stick as transparent TPE;

2) The specific gravity of TPU varies widely, ranging from 1.0 to 1.4, while TPE is between 0.89 to 1.3, mainly in the form of blends, so the specific gravity changes greatly;

3) TPU has better oil resistance, while TPE has relatively poor oil resistance;

4) TPU burns with a light aroma, with less and light smoke, and there is a slight explosion sound when it burns, TPE has a light aroma when burning, and the smoke is less and light;

5) TPU's elasticity and elastic recovery performance are better than TPE;

6) TPU temperature resistance is -60 degrees Celsius to 80 degrees Celsius, TPE is -60 degrees Celsius to 105 degrees Celsius;

7) In terms of appearance and feel, for some overmolded products, TPU products have a rougher feel and strong frictional resistance than TPE products; while TPE products have a delicate and soft feel and weaker friction performance.

In general, the TPU resistance band is transparent and frosted, light and soft, has good resilience, good toughness, and is not easy to break. It is suitable for knitwear collar cuff hemming and shoulder seam side seam setting. The TPE resistance band has a variety of colors, is comfortable to the touch, has a high stretch rate, and has excellent resilience. It is suitable for use on fitness equipment.

Post time: May-31-2021